Posted on: 15 March 2016

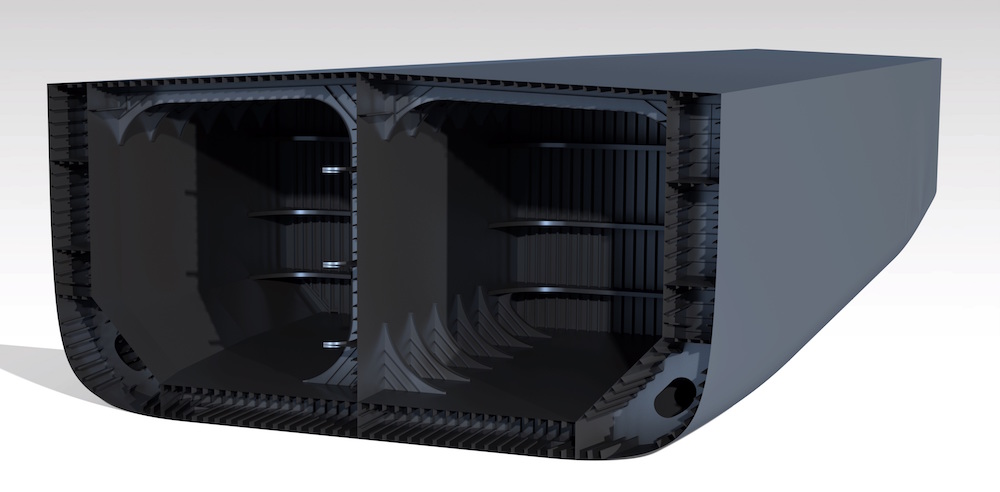

The dramatic reduction in the time needed to check the structure, seakeeping and stability of new vessels and floating offshore units is being delivered through the use of a powerful 3D model which links directly to BV’s entire VeriSTAR suite of calculation tools.

Philippe Donche-Gay, Executive Vice-President, Marine & Offshore Division, says, “The power and ease of use of our new modelling software enables us to build a detailed 3D model of the proposed vessel very quickly, much more quickly than has ever been achieved before. That model interfaces directly with all our tools, meaning no data has to be entered twice, saving time and improving accuracy. Ship designers, shipyards, ship owners and offshore operators are going to benefit from major time and cost savings as we move our entire design and plan approval onto this new digital platform.”

Bureau Veritas’ new system is based on a strategic partnership with France’s Dassault Systèmes under which Bureau Veritas will use Dassault’s 3DEXPERIENCE platform to dramatically speed the creation of detailed 3D models of ships and floating offshore units.

The model allows end-to-end calculation without data re-entry through all the analysis and design phases, then will facilitate construction by simplifying the order of steel cutting. It will then go on to form a digital twin of the vessel or unit and be maintained in an as-is state for the life of the unit. This will facilitate maintenance and repair or conversion decisions.

A pilot project with the well-known Chinese design institute SDARI has been completed. Two new aframax and suezmax tanker projects from this designer were modelled by using the new 3D platform. The models were then automatically transferred into BV’s structural calculation software VeriSTAR Hull, in which the latest CSR Rules for oil tankers are fully integrated. The process enabled the designer to check compliance with the CSR Rules in a very quick, powerful and easy way.

Says Donche-Gay, “What’s different about this new platform, and what creates the time and cost saving, is the power of the modelling software. We now only have to build one model and we do not have to create multiple data sets to use different tools for hull strength, stability and other vital calculations. We also improve traceability in-house as there is only one data entry.”