Posted on: 18 January 2022

Bureau Veritas (BV), a leader in testing, inspection and certification, and NAPA, the leading maritime software, services and data analysis provider, and have announced their partnership to enable more effective and widespread use of 3D models in the class approval process.

Through this partnership, the two parties seek to improve the overall efficiency and accuracy of future vessel design and solve the current challenges associated with 2D drawings. While naval architects use 3D models to design ships, the assessment of these designs by class ensure they meet relevant safety and compliance specifications, requiring them to be translated into 2D and then back again into 3D. This process is not only time-consuming, but it also slows down communication between class societies and designers and can lead to errors in the design.

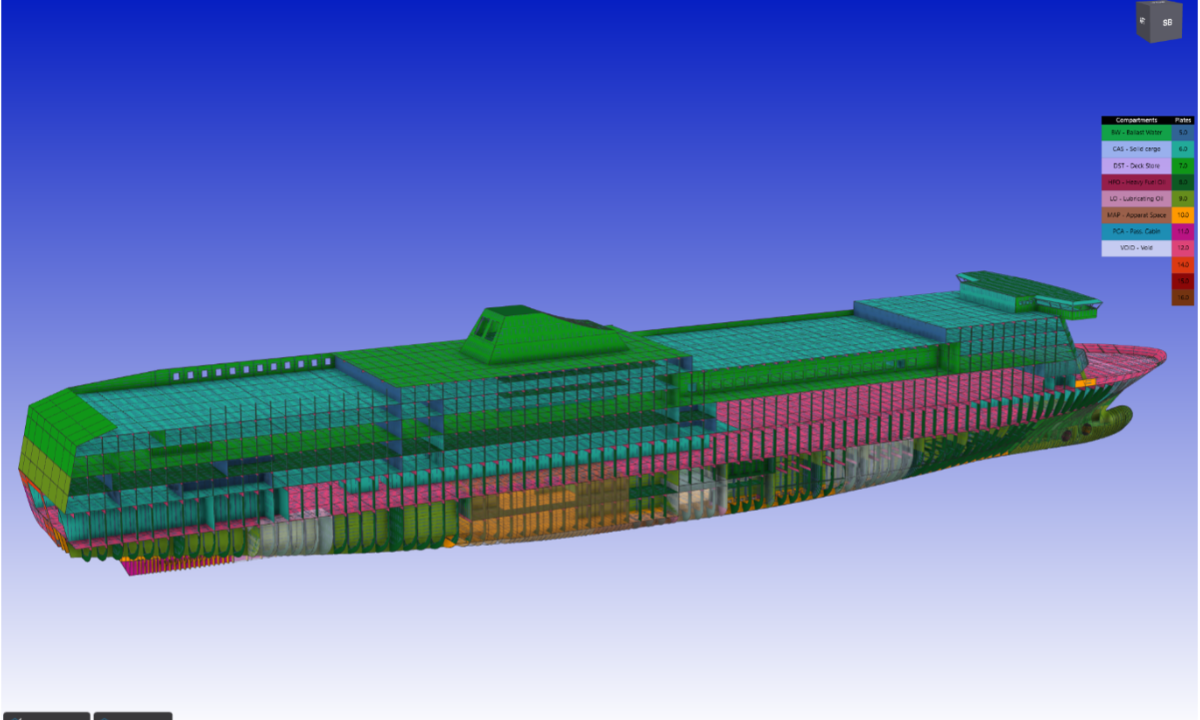

NAPA and BV have set out to change this, in line with a shared vision to transform the design process with input from major shipbuilding, engineering and consulting companies. The outcome includes the creation of a new process that enables BV to perform its rule checks without needing to re-create 3D models from 2D drawings by integrating the neutral OCX format (OCX: Open Class eXchange).

Mikko Forss, EVP Design Solutions at NAPA, said: “NAPA has been at the forefront of 3D design for many years, and designers, class societies, and software companies all agree that the shift to 3D needs to happen in the approval process as well. We’re proud to be driving that transition forward for our industry with new partnerships and by developing solutions that enable collaboration on the same 3D model throughout the design process, with better results for all involved. We’re looking forward to continuing to innovate with BV and are excited to see the benefits of the solution realized on a real-life project.”

Laurent Leblanc, Senior Vice President Technical & Operations at Bureau Veritas Marine & Offshore, said: “This innovative breakthrough means that we have a viable and effective solution to use 3D model-based approval. The shift to 3D approval is important as it underpins what will be the next generation of vessel designs. It also means we will be able to collaborate more closely and more efficiently with designers to better iterate vessel designs to meet the safety and sustainability challenges of the future.”

Once the designer shares hull data based on the OCX format from its design software, BV imports it into NAPA Steel to automatically generate the calculation models used in BV’s rule-checking software: MARS (prescriptive rule check) and VeriSTAR Hull (finite element analysis).

In addition, BV provides access to its web-based collaborative platform (VeriSTAR Project Management) to share the comments and the progress of the design review with shipyards, designers and shipowners in real-time.

Leaning on the OCX format, which is vendor-neutral and has the potential to be widely used in vessel design, this research opens up 3D model-based approval to a variety of potential users, companies, and software applications. NAPA and BV are now progressing development by applying this 3D model-based approval process with leading shipbuilders.